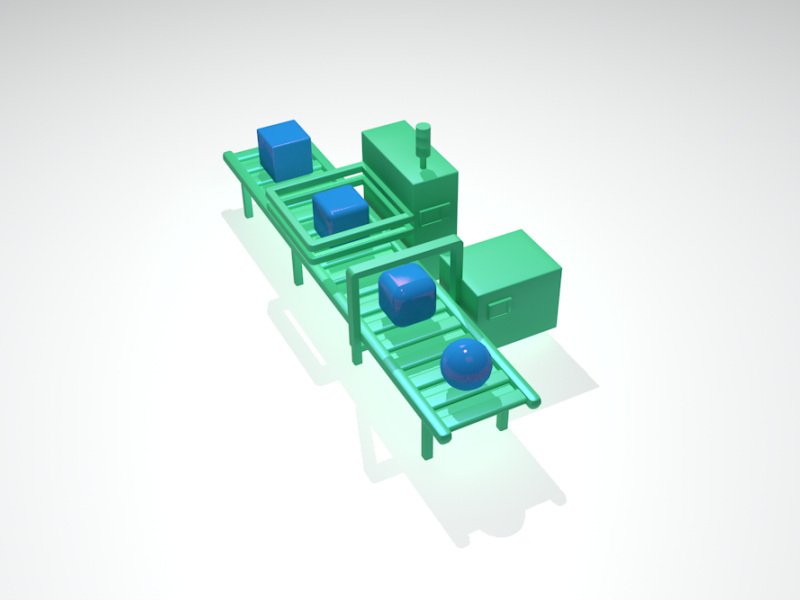

Production Management

At Bortnick Consulting Services (BCS), we understand that effective production management is crucial for achieving operational excellence and delivering high-quality products. Our team of experienced professionals specializes in production management, offering comprehensive solutions to optimize your manufacturing processes and drive efficiency throughout your operations.

Quality Control and Assurance

Maintaining consistent product quality is paramount to the success of your business. BCS supports you in implementing robust quality control and assurance processes. We help you develop comprehensive quality standards, conduct thorough inspections, and implement statistical process control (SPC) methodologies. By leveraging our expertise in quality management systems, we ensure that your products meet or exceed industry standards, enhancing customer satisfaction and reducing the risk of costly rework or recalls.

Lean Manufacturing and Continuous Improvement

We believe in the principles of lean manufacturing and continuous improvement. Our team employs lean methodologies to identify and eliminate waste throughout your production processes. By implementing value stream mapping, 5S methodology, and Kaizen events, we help you optimize workflow, reduce lead times, and enhance overall productivity. Through ongoing monitoring and data analysis, we identify opportunities for improvement and work collaboratively with your team to implement sustainable changes, driving long-term efficiency gains.

Supplier and Vendor Management

Managing relationships with suppliers and vendors is critical for ensuring a smooth production process. BCS assists you in developing effective supplier management strategies, including supplier selection, performance monitoring, and contract negotiation. We help you establish clear communication channels, streamline procurement processes, and implement vendor evaluation systems. By fostering strong partnerships with your suppliers and vendors, we enhance supply chain reliability, reduce lead times, and minimize disruptions.